It is really a headache when you got a CNC machining part that was deformed, not flat so you could not assemble it, as a result, it stops your project.

The deformation of aluminum alloy processing is a difficult problem faced by many CNC machining plants. So how can the aluminum alloy not be deformed? First of all, we must understand the reasons for the deformation of aluminum alloy in the CNC machining process.

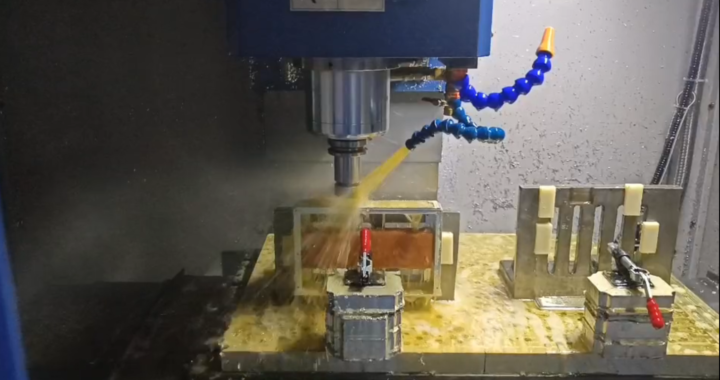

Aluminum alloy processing is completed by cutting the material with a tool. The cutting process is the extrusion process. The extrusion process will generate a lot of heat, the material will expand, and the grain of the material will change. After cooling, it will shrink and the grain structure will change, resulting in the metal Residual stress will be generated inside, this stress will be deformed if not eliminated, and the size will also change.

The solution to solve this problem is to divide the aluminum alloy machining process into roughing and finishing. After the roughing is completed, the parts are heat-treated to fully release the cutting stress and residual stress of the parts, and then finish machining; the advantages are:

-1> The influence of residual stress on machining deformation can be reduced. After rough machining is completed, it is recommended to use heat treatment to remove the stress caused by rough machining of the part, which can reduce the influence of stress on finishing.

-2> Improve machining accuracy and surface quality. After the roughing and finishing are separated, the finishing is only a small allowance, and the processing stress and deformation are small, which can greatly improve the quality of the parts.

Quick Metal Part could provide professional workmanship to avoid deformation parts and please send your CAD file if you have flatness requirement on the part surfaces.