Quick Metal Part provides professional CNC machining services with a short lead time and high quality for a long time.

To quickly realize your designing part and mass production for your urgent needs, CNC machining services at Quick Metal Part would offer the following advantages:

- High precision machining and we can keep tolerance +/- 0.01 – 0.02mm;

- Widely industrial serviced and gained satisfaction & good compliments from our customers;

- Quick machining for kinds of metal as well as plastic material;

- Especially good at machining complicated parts;

- Production volumes from one to unlimited quantity;

- Save your huge investment in tooling and time;

- Rapid turnaround to ensure your urgent lead time;

- Excellent part surface finishes;

- Help your products to be the best selling in the marketing.

Do you want to get a quick quote – Please send us the following files & information to email sales@quickmetalpart.com and we would quote within 1 Working Day.

- CAD file with STEP or IGS format ;

- CNC Machining Material: Please find the following Material List – CNC Material Table – Metal & Non-Metal;

- Finish Treatment: Anodizing, Painting, Bead-blasting, Electropolished, Nickel Plating etc.;

- Parts Quantity that you need: From 1pcs to unlimited quantity that you want to order.

CNC Material Table – Metal & Non-Metal

| Item | CNC Material | CNC Material Cost – Metal | Max. Thickness |

| 1 | AL 6061 | Middle Cost | 150mm |

| 2 | AL 606-T6 | Middle Cost | 150mm |

| 3 | AL 6061-T651 | Middle Cost | 90mm |

| 4 | AL 5052 | Middle Cost | 80mm |

| 5 | AL 502-H32 | Middle Cost | 75mm |

| 6 | AL 5052-H112 | Middle Cost | 70mm |

| 7 | AL 5083 | Middle Cost | 120mm |

| 8 | AL 7075 | Middle Cost | 100mm |

| 9 | AL 6082 | Middle Cost | 150mm |

| 10 | AL 6082-T6 | Middle Cost | 150mm |

| 11 | AL 7075-T651 | High Cost | 80mm |

| 12 | AL 380 | High Cost | 70mm |

| 13 | AL 2017 | Middle Cost | 90mm |

| 14 | AL 2024 | High Cost | 80mm |

| 15 | AL 5056 | High Cost | 80mm |

| Item | CNC Material | CNC Material Cost – Non Metal | Max. Thickness |

| 1 | PEEK | Very High Cost | 100mm |

| 2 | PPS | Very High Cost | 60mm |

| 3 | ABS | Low Cost | 220mm |

| 4 | POM | Middle Cost | 130mm |

| 5 | PC | Middle Cost | 100mm |

| 6 | PA6 | Middle Cost | 150mm |

| 7 | PMMA | Middle Cost | 100mm |

| 8 | PP | Middle Cost | 100mm |

| 9 | PVC | Middle Cost | 60mm |

| 10 | PTFE | Middle Cost | 100mm |

| 11 | FR-4 | High Cost | 60mm |

How to Save the CNC Machining Part Cost

We are often being asked how to reduce the CNC machining part cost?

Well. This is really a common question from many customers and here Quick Metal Part would like to list the following reasons:

- CNC Machining Time: This is the essential factor for why your CNC machining part cost is so high – The long machining time, the higher CNC machining cost;

- CNC Part Tolerance: Tolerance is the most important satisfaction for most customers that we need to take care of it – The cost will be higher for small tolerances;

- Select the economic CNC part Material and Finish Treatment – Please see the material list from our CNC machining Menu;

- Increase the CNC Part wall thickness when you designing the CNC machining parts;

- For the holes and threads of your CNC machining parts – please try to tap the standard hole size and threads;

- Change the inner corner to Radius to save the cost of cleaning the corner of the parts.

Consider These Factors Before Lunch Production Your Designed CNC Parts

We are very happy to feedback to the Process FMEA when we got your CNC machining part RFQs and these factors that we always discuss with our clients to quickly improve your designing parts in the production:

- Your CNC machining part needs what kind of material and finish treatment – it meant what the part-work environment is: Withstand high temperature, using it at the outside door,…etc;

- Choice the production process to realize your CNC machining part – Based on the part structure and material, we will advise the best solutions for you;

- Reviewing Your CAD file so we can advise if any updates are needed for the part profile, structure, and details if could be machined or not.

How to Reduce the Part Deformation During CNC Machining?

It is really a headache when you got a CNC machining part that was deformed, not flat so you could not assemble it, as a result, it stops your project.

The deformation of aluminum alloy processing is a difficult problem faced by many CNC machining plants. So how can the aluminum alloy not be deformed? First of all, we must understand the reasons for the deformation of aluminum alloy in the CNC machining process.

Aluminum alloy processing is completed by cutting the material with a tool. The cutting process is the extrusion process. The extrusion process will generate a lot of heat, the material will expand, and the grain of the material will change. After cooling, it will shrink and the grain structure will change, resulting in the metal Residual stress will be generated inside, this stress will be deformed if not eliminated, and the size will also change.

The solution to solve this problem is to divide the aluminum alloy machining process into roughing and finishing. After the roughing is completed, the parts are heat-treated to fully release the cutting stress and residual stress of the parts, and then finish machining; the advantages are:

-1> The influence of residual stress on machining deformation can be reduced. After rough machining is completed, it is recommended to use heat treatment to remove the stress caused by rough machining of the part, which can reduce the influence of stress on finishing.

-2> Improve machining accuracy and surface quality. After the roughing and finishing are separated, the finishing is only a small allowance, and the processing stress and deformation are small, which can greatly improve the quality of the parts.

Quick Metal Part could provide professional workmanship to avoid deformation parts and please send your CAD file if you have flatness requirements on the part surfaces.

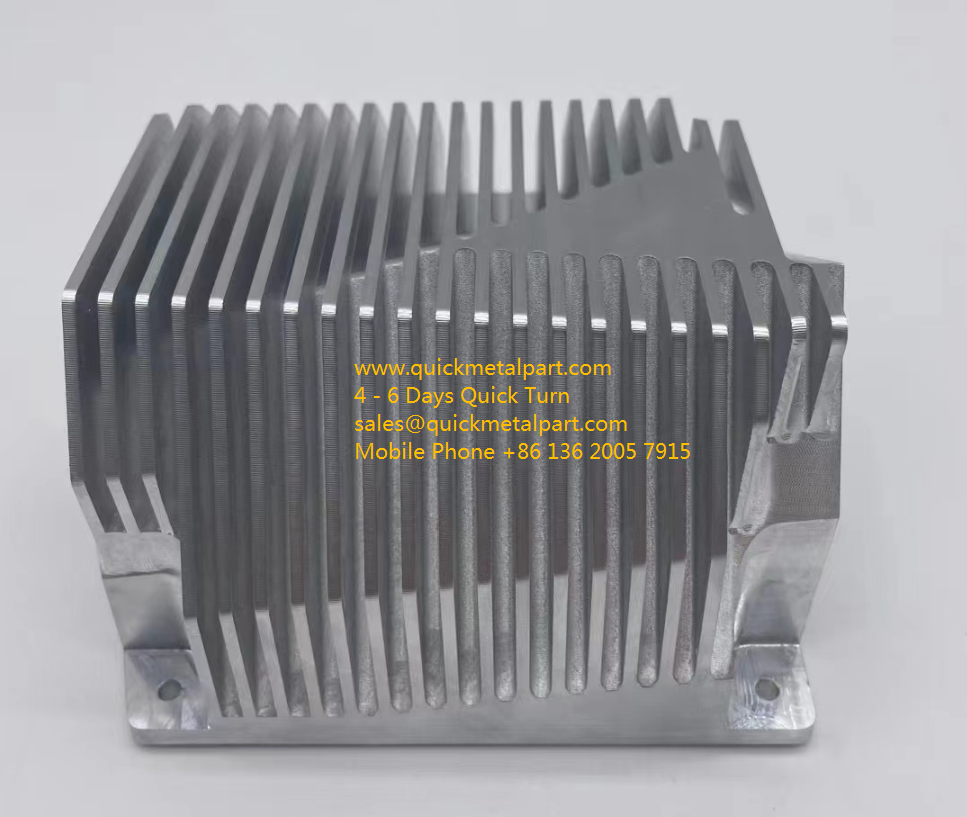

Here are some CNC part photos –

Key Words: CNC Machining Part, CNC Turning Part;